GorrillaBot

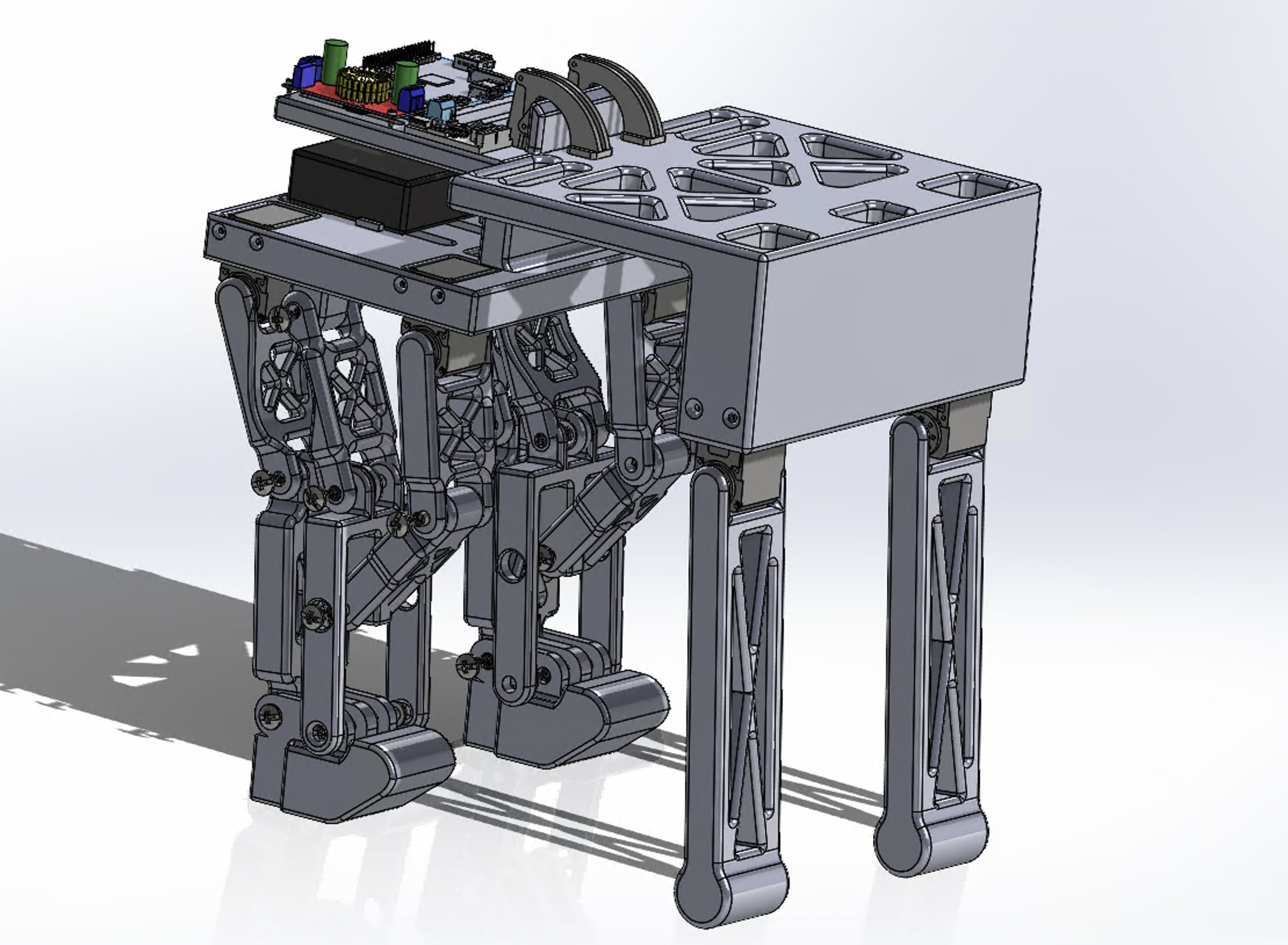

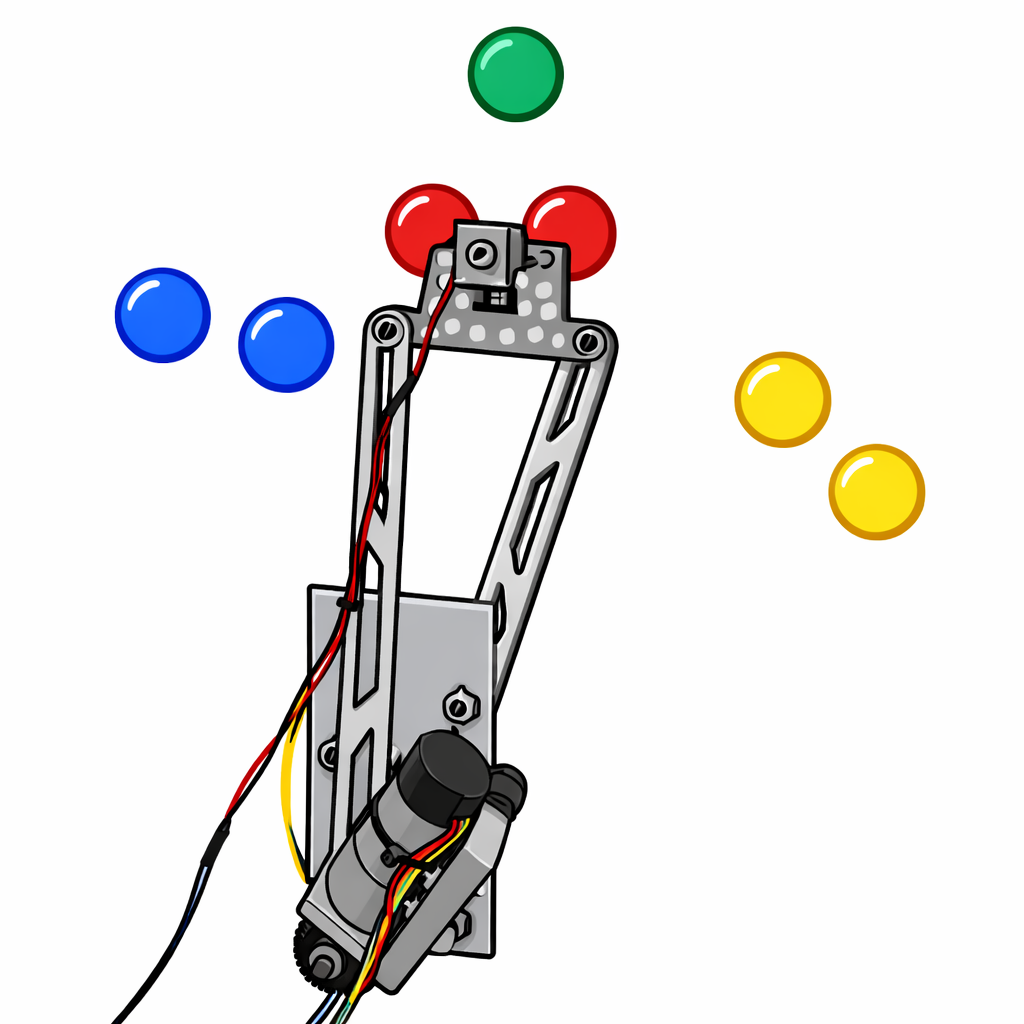

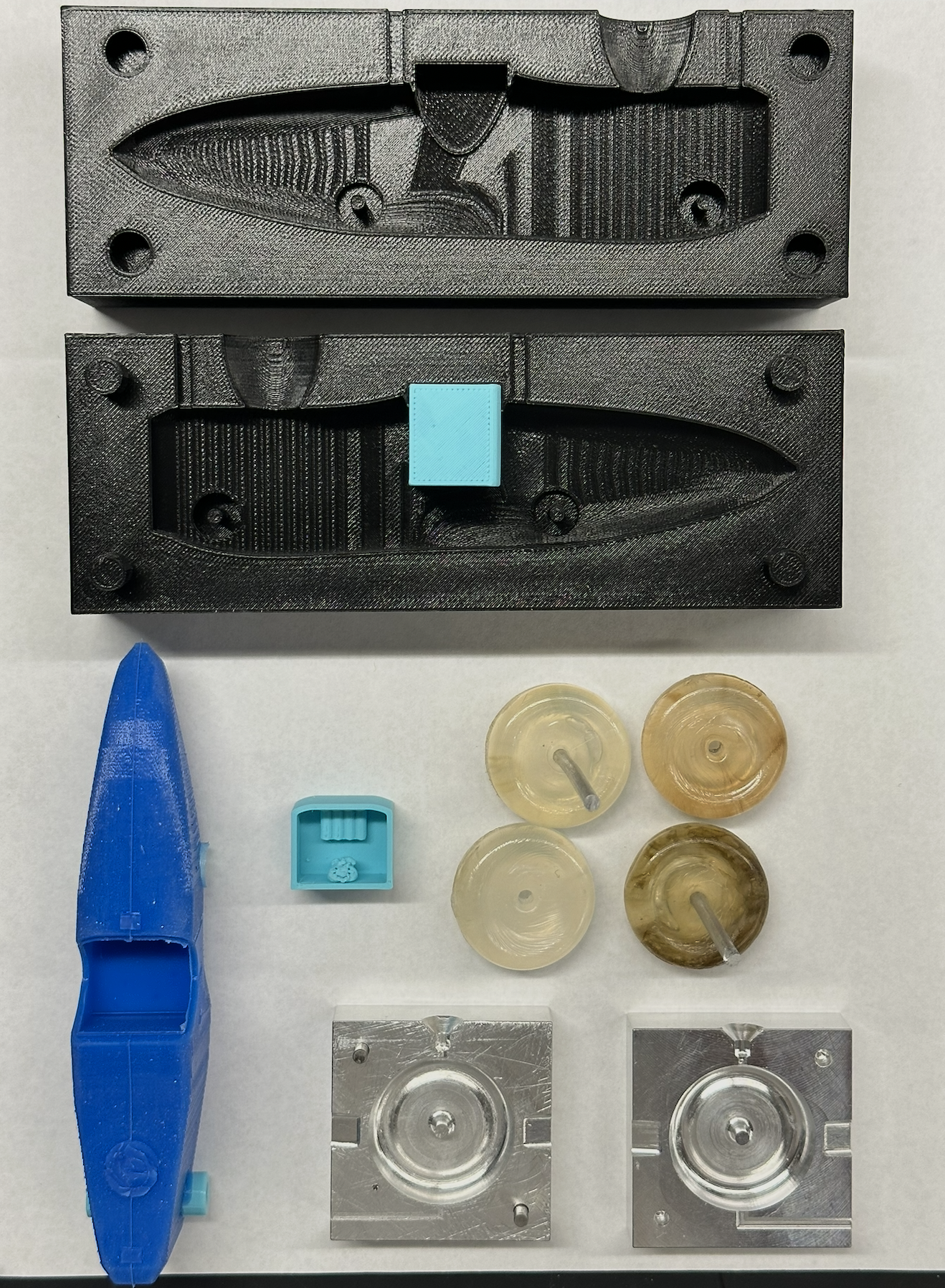

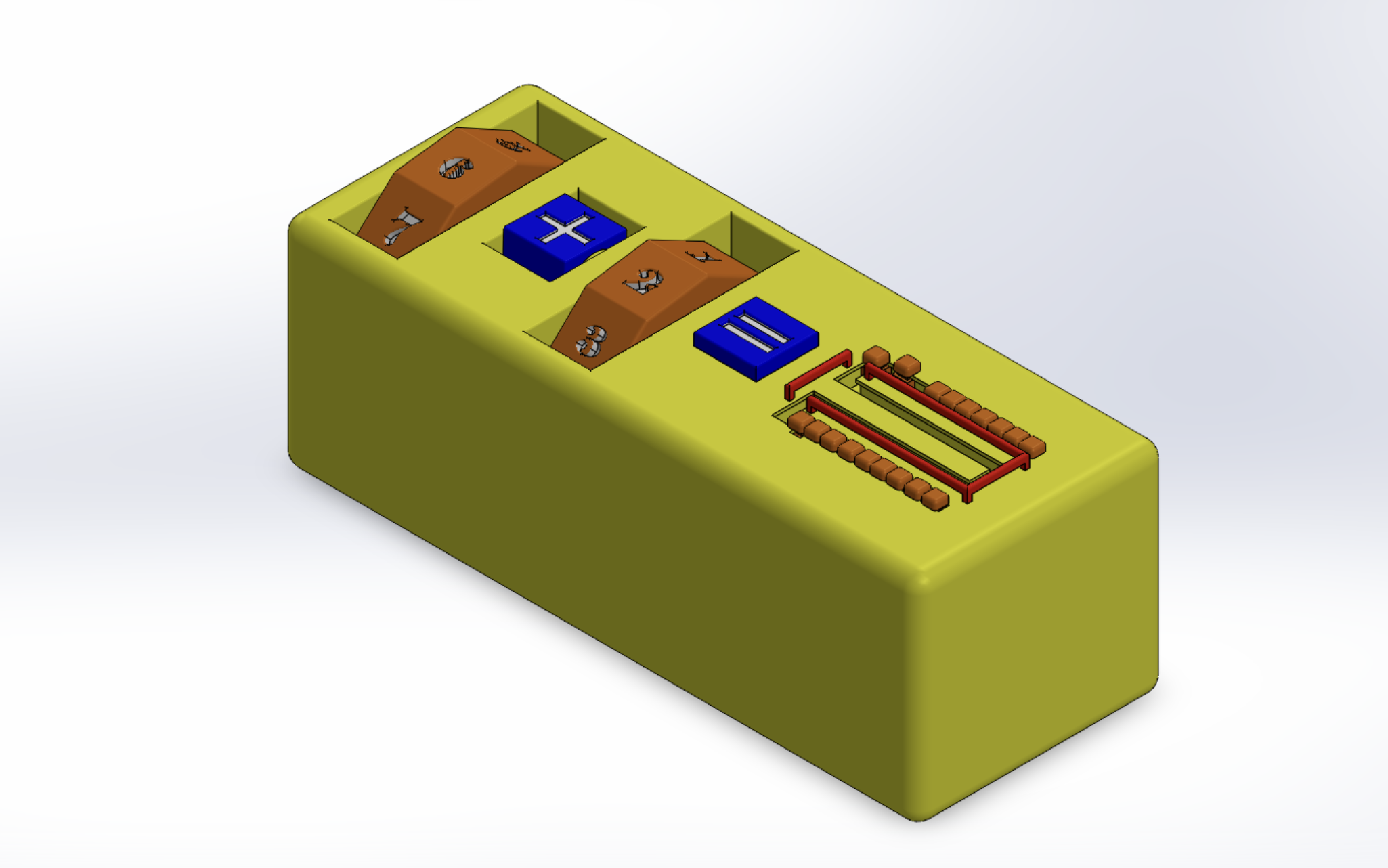

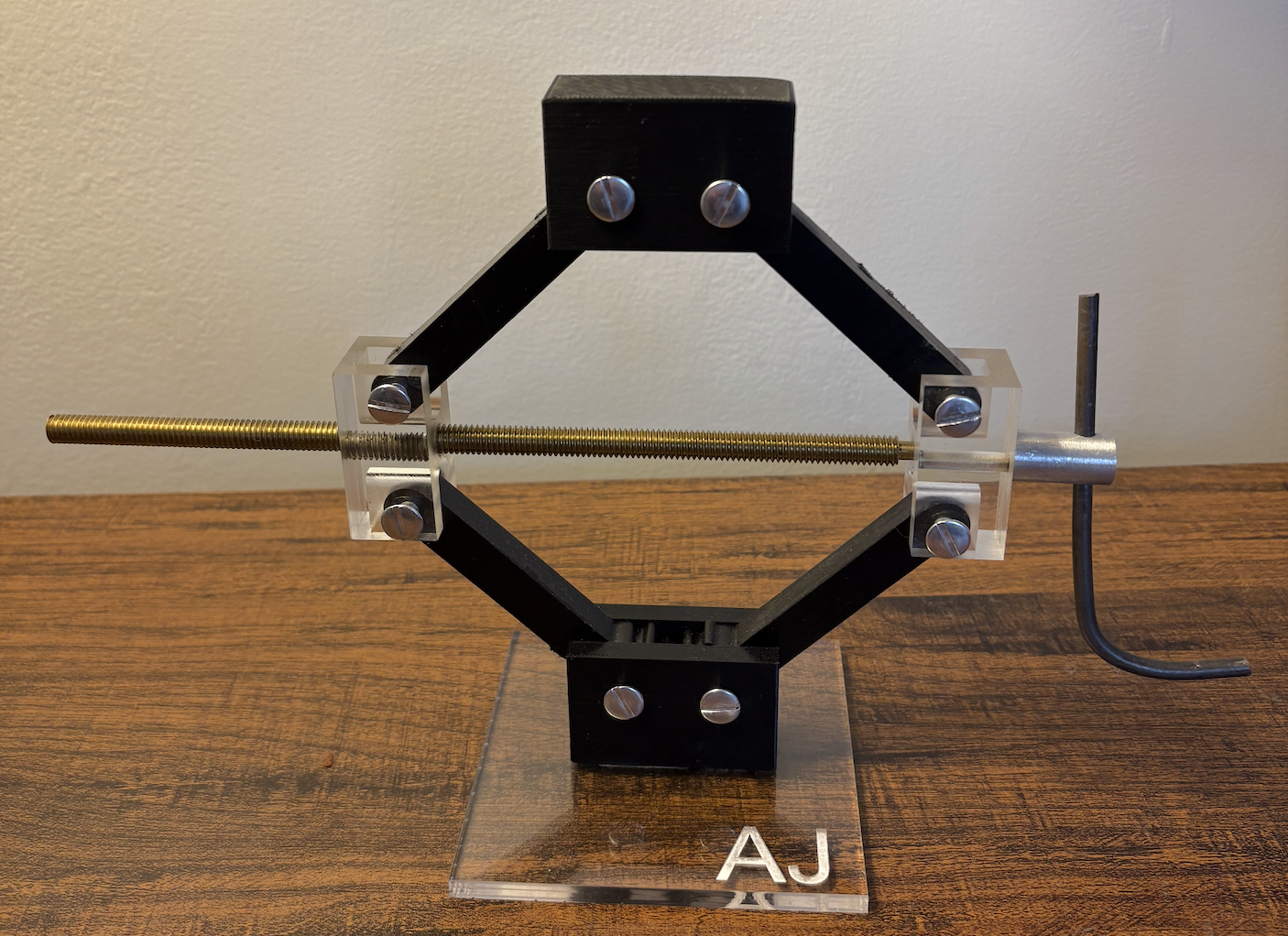

Our initial goal was to build a custom bipedal robot capable of independently walking on two legs and transform into a quadrupedal stance using a servo-actuated hinge - as seen in the first image. As we got closer to the final deadline and realised our final grading was exlusively based on the speed of the robot - we pivoted!

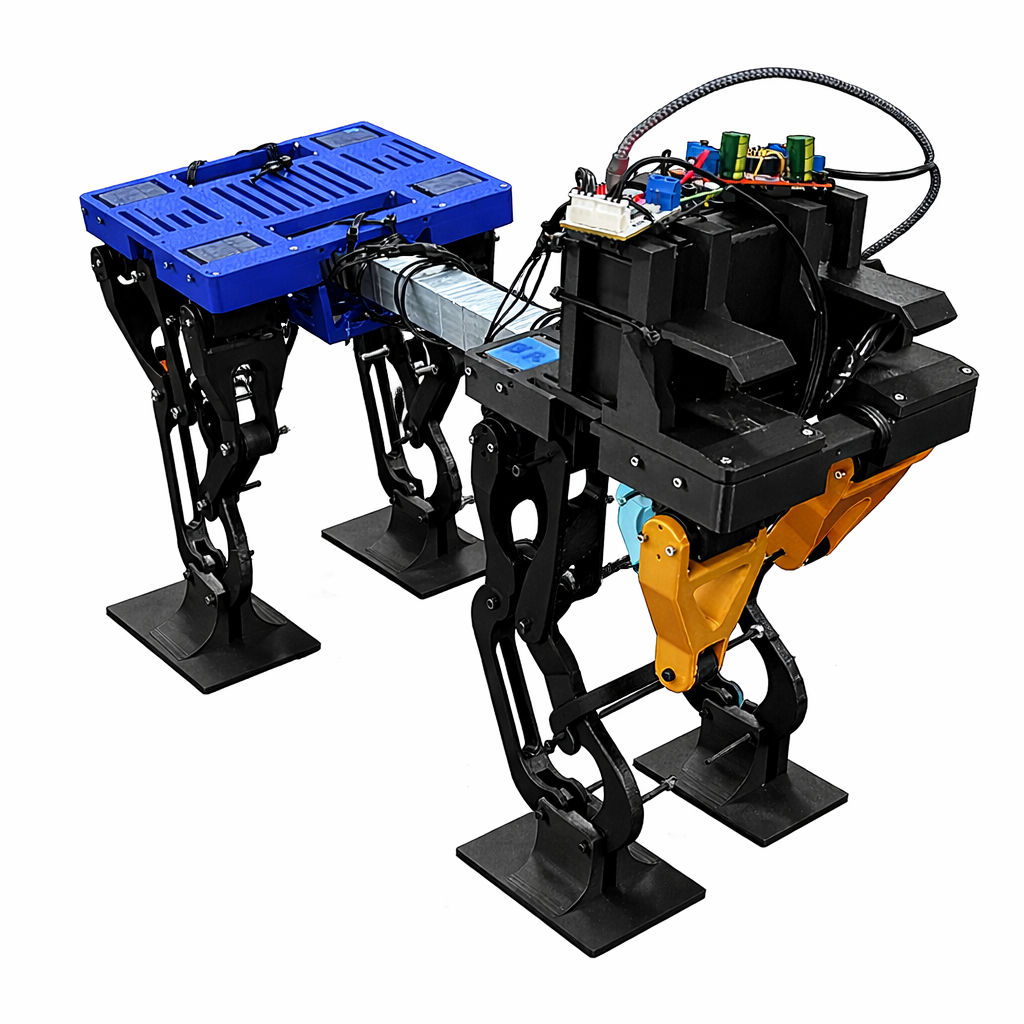

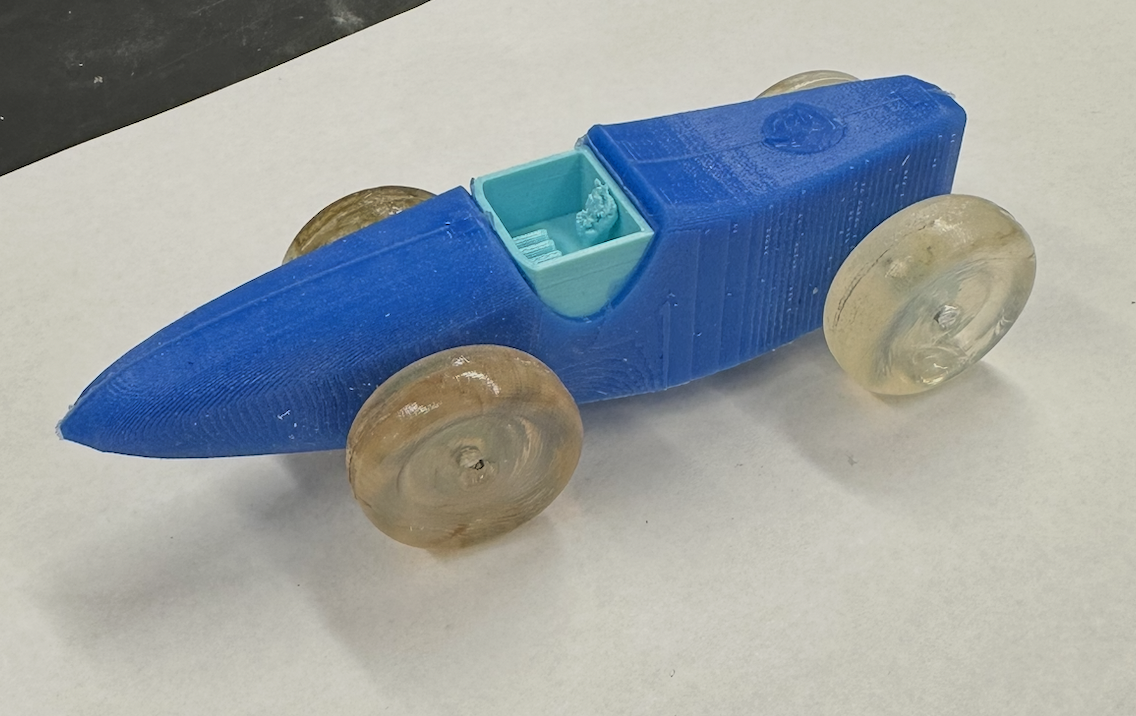

We instead connected two of our existing bases together using scrap alumnium and zipties and build a quadrapedal robot that was fast enough to get us the highest grade! All in the last 2 days!

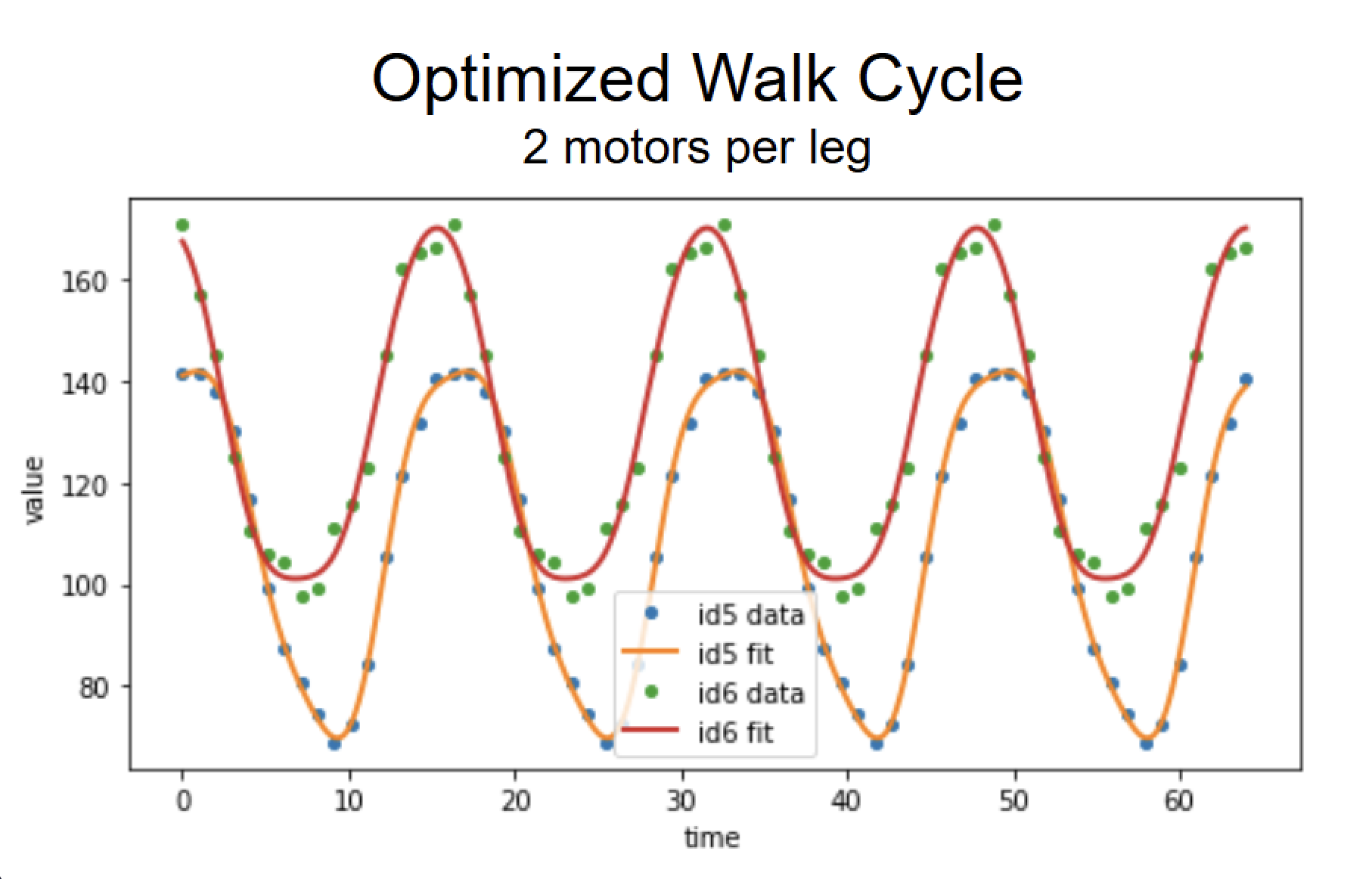

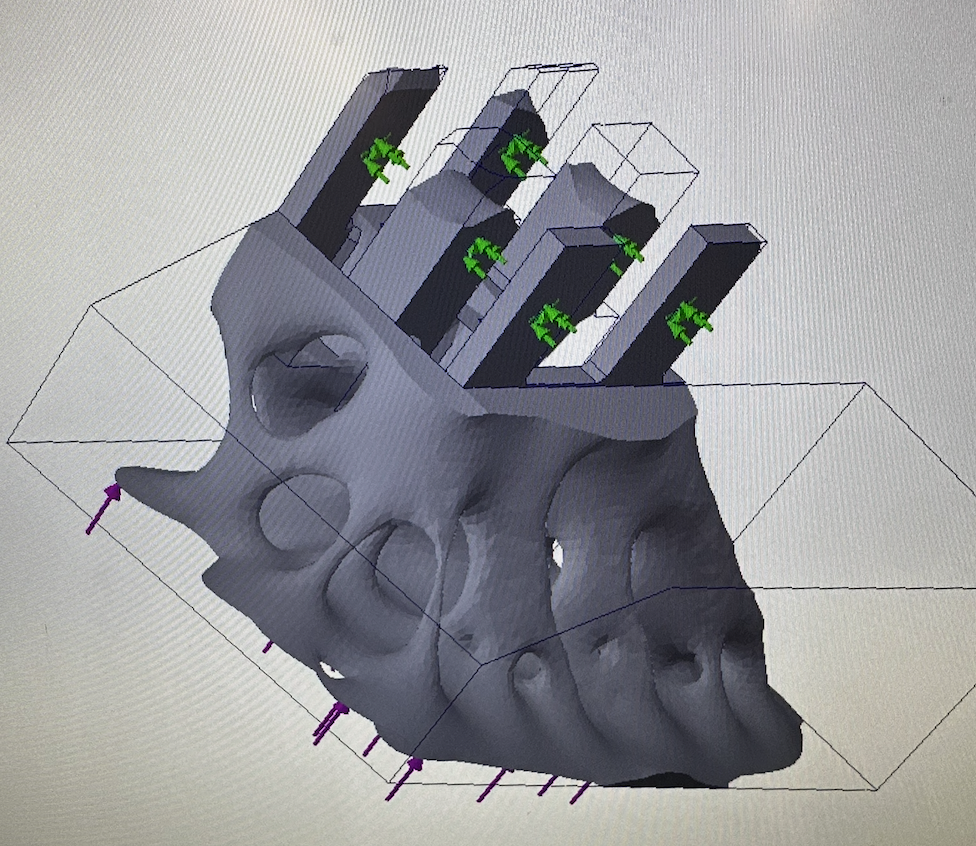

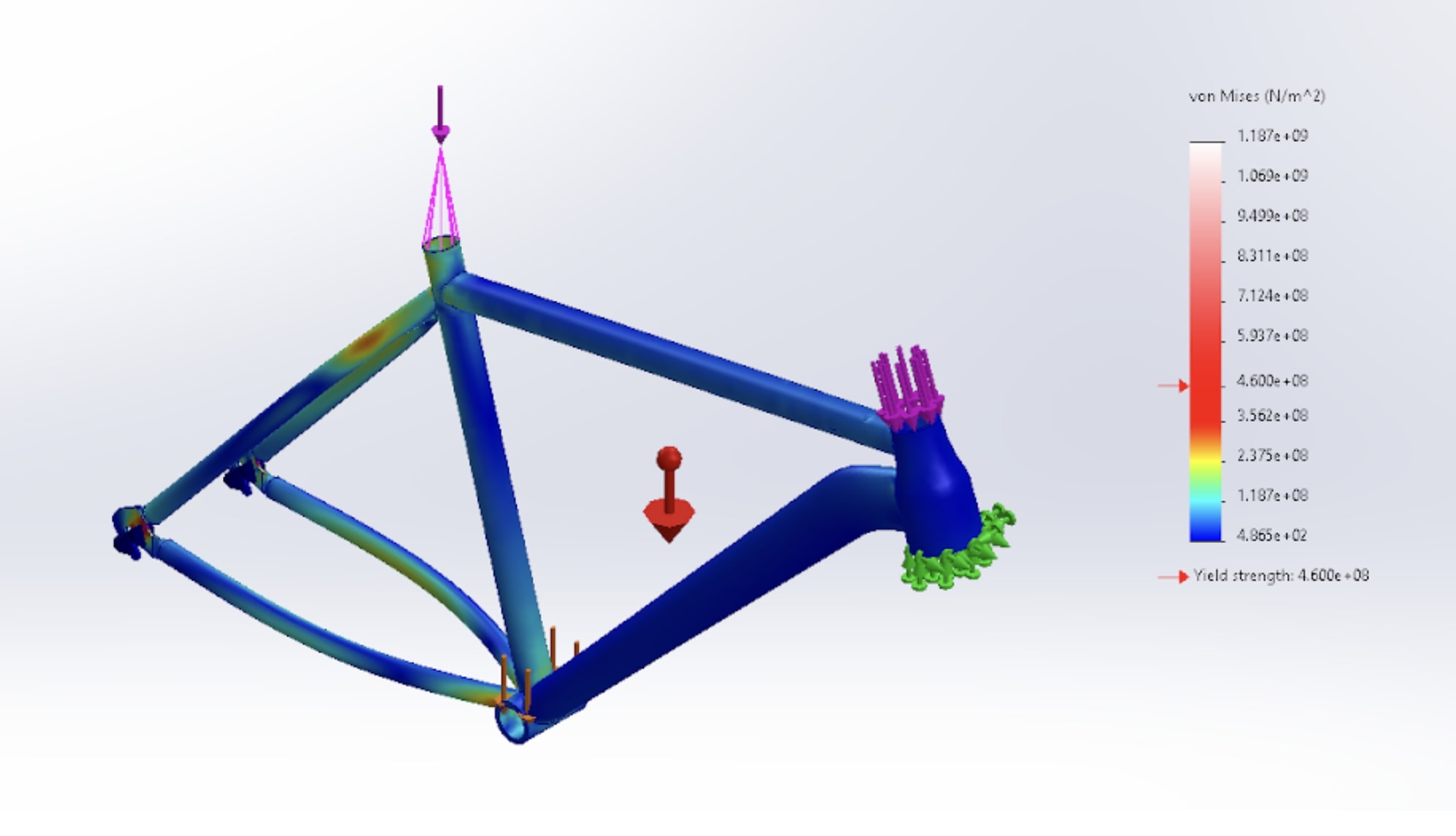

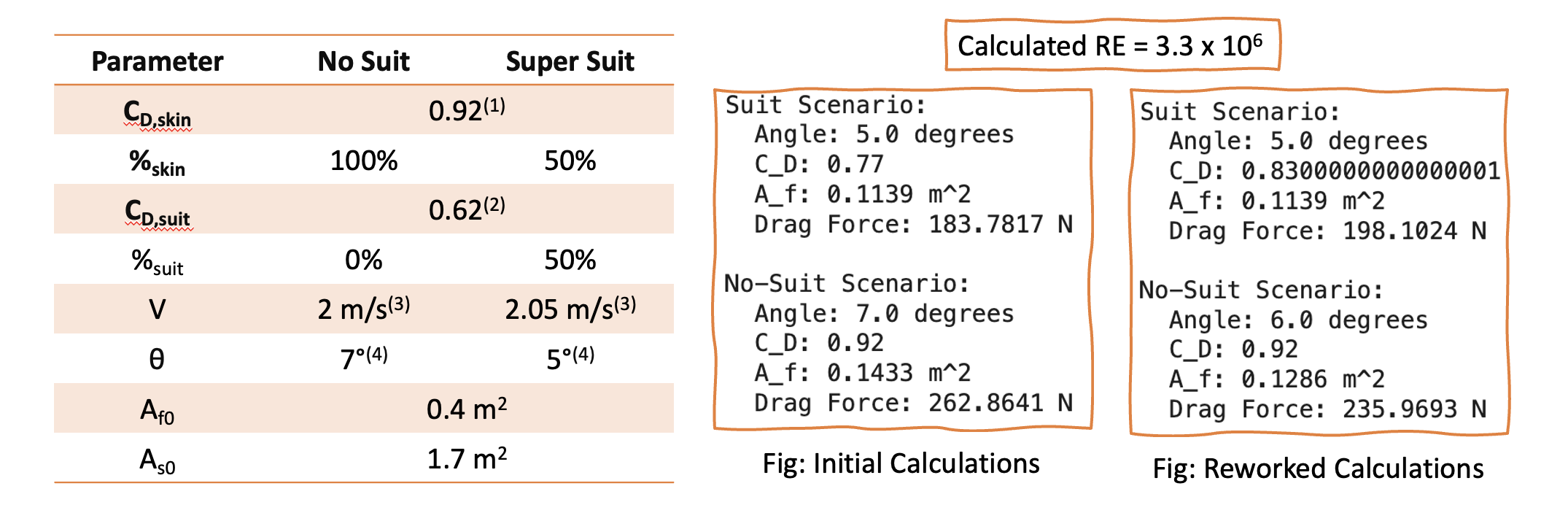

There were many important takeaways from this project, from the extensive (bordering on absurd) iterations the could have been minimised by more intentional thought to learning how to adapt engineering projects on the fly. Some of the hard skills learnt range from Robot CADs, Algerbraic topology for pieces, Sim2Real Python simulations, Developing gait patterns, etc.

View Project